Introduction

Welcome to the Maker Space wiki!

Here you will find (hopefully) all the information you could possibly want to know about our hackspace, how it works, what facilities we have and how to use them.

In progress

This wiki is still being populated. For now you may still need to head to the old wiki for some information.

The Space

Maker Space is split into four main locations/sections:

- Ground floor corridor

- Ground floor workshop

- South/tall/big basement workshop

- North/short/small basement workshop

Prepare yourself for a Microsoft Copilot guided tour through our space.

Pretty much all of the text in the above pages was generated by asking Copilot to "in the style of an estate agent, describe

Ground Floor Corridor

As you step into this industrial haven, the corridor unfolds before you—a seamless blend of practicality and aesthetics. The heartbeat of this workspace, the corridor stretches like a silent river, connecting different realms within the building. It’s not merely a passageway; it’s a conduit of creativity and collaboration.

At one end of the corridor, behold the pièce de résistance - the laser cutter. Its sleek metallic frame stands like a sentinel, ready to transform raw materials into precision-cut masterpieces. The hum of the extraction adds a symphonic undertone to the corridor’s rhythm.

Ground Floor Workshop

Step into this vibrant hub of innovation, where imagination takes tangible form. Our main workshop is more than just a room - it's a canvas for your wildest ideas.

Picture a symphony of activity. The main workshop sprawls across the floor, partitioned into multiple work areas. Whether you're assembling a PCB or making tote bags, there's a spot for your creative endeavors.

Our electronics workspaces, a place where wires tangle like ivy, components sprawl like fallen leaves, and soldering irons hum like caffeinated bees.

The soldering stations wear battle scars. Burn marks, flux residue, and tangled solder wicks - they tell tales of countless connections forged. The air smells of molten dreams and a hint of desperation.

Dive in, untangle wires, and let sparks fly. Who knows? Your next invention might emerge from this delightful chaos.

In our cosy goldfish bowl you will find several PC workstations - each a digital canvas awaiting your command. These machines hum with potential, their screens reflecting the glow of countless projects.

Currently we have two general purpose machines: one Ubuntu 24.04 and one Windows 10, and one dedicated CAD machine running Windows 10, where 3D models take shape, and blueprints come alive. Whether you're designing a futuristic skyscraper or a whimsical teapot, these stations empower your vision.

Each wall of the room is clad in a labyrinth of industrial shelving. Each shelf cradles a universe of components, parts and tools.

Welcome to the hackspace lounge, a tranquil corner where making takes a breather.

Behold at what some consider the most critical items in the space: our tea and coffee making facilities. The aroma of freshly brewed chai mingles with the robust scent of freshly ground beans. Choose your potion: tea or double-shot espresso? Both enjoyed from the Royal Doulton with the hand-painted periwinkles.

Nestled against the wall, our plush sofa beckons. Sink into its embrace - a refuge for tired hackers and dreamers alike. Whether you're pondering the next steps for your current project or just need a power nap, this sofa cradles your thoughts.

Open the fridge, and you'll find a treasure trove: cold brews, artisanal sodas, and perhaps a rogue slice of leftover pizza. It’s like Narnia, but with more caffeine. But please note some items belong to members or cost money if you'd like to consume them.

The bookcase stands tall, its shelves sagging under the weight of knowledge. Dusty hardcovers, dog-eared paperbacks, and a few mysterious tomes - they’re all here.

The storage wall is a vast expanse of shelving, stretching from floor to ceiling, each unit brimming with a variety of tools, components, and materials. Every inch is utilized to its fullest potential, packed full of tools, parts and materials just waiting for the right project to come along.

The south side of this shelving is dedicated to storage for member's personal items.

Welcome to the vibrant hub of creativity within this dynamic hackspace: the breakfast bar. This inviting space is designed to foster collaboration and provide a comfortable spot for members to create and connect.

The breakfast bar table is a sleek, modern fixture, crafted from high-quality materials that blend functionality with style. It's spacious surface offers ample room for enjoying a quick snack, tinkering on a project, or engaging in lively discussions about the latest projects and ideas. The bar stools, with their ergonomic design, ensure comfort during those longer brainstorming sessions.

Strategically located within the hackspace, this area is bathed in natural light, creating a warm and welcoming atmosphere. The surrounding decor is thoughtfully curated to inspire creativity, with vibrant artwork and innovative designs adorning the walls.

Whether you’re taking a break from a challenging project or simply looking to network with fellow makers, the breakfast bar table area is the perfect spot.

Adjacent to the breakfast bar is the cutting-edge communication hub within the hackspace: the amateur radio setup. This area is meticulously designed for enthusiasts and hobbyists who are passionate about radio technology and communication.

This amateur radio setup is more than just a collection of equipment; it's a gateway to a world of communication and exploration. Whether you're a seasoned operator or new to the hobby, this space is designed to inspire and support your passion for radio technology.

Step into this exceptional amateur radio setup and experience the thrill of global communication right from the heart of our hackspace!

Here we have our 3D printing station. This area is a dream come true for any maker, featuring top-of-the-line equipment that promises precision and reliability.

To the left, you’ll find the renowned Prusa MK3. Its user-friendly interface and reliable performance make it an indispensable tool for both beginners and seasoned professionals.

Complementing the Prusa MK3 is the cutting-edge Bambu Lab P1S. This advanced 3D printer is celebrated for its speed and versatility, capable of producing high-quality prints in a fraction of the time. With its sleek design and state-of-the-art features, the Bambu Lab P1S is perfect for those looking to push the boundaries of their creativity.

The 3D printing station is thoughtfully arranged to maximize efficiency and inspire innovation. Each printer is strategically positioned to allow for seamless workflow, with ample workspace for preparing and finishing prints. The station is well-lit and equipped with all the necessary tools and materials, ensuring that every project can be executed to perfection.

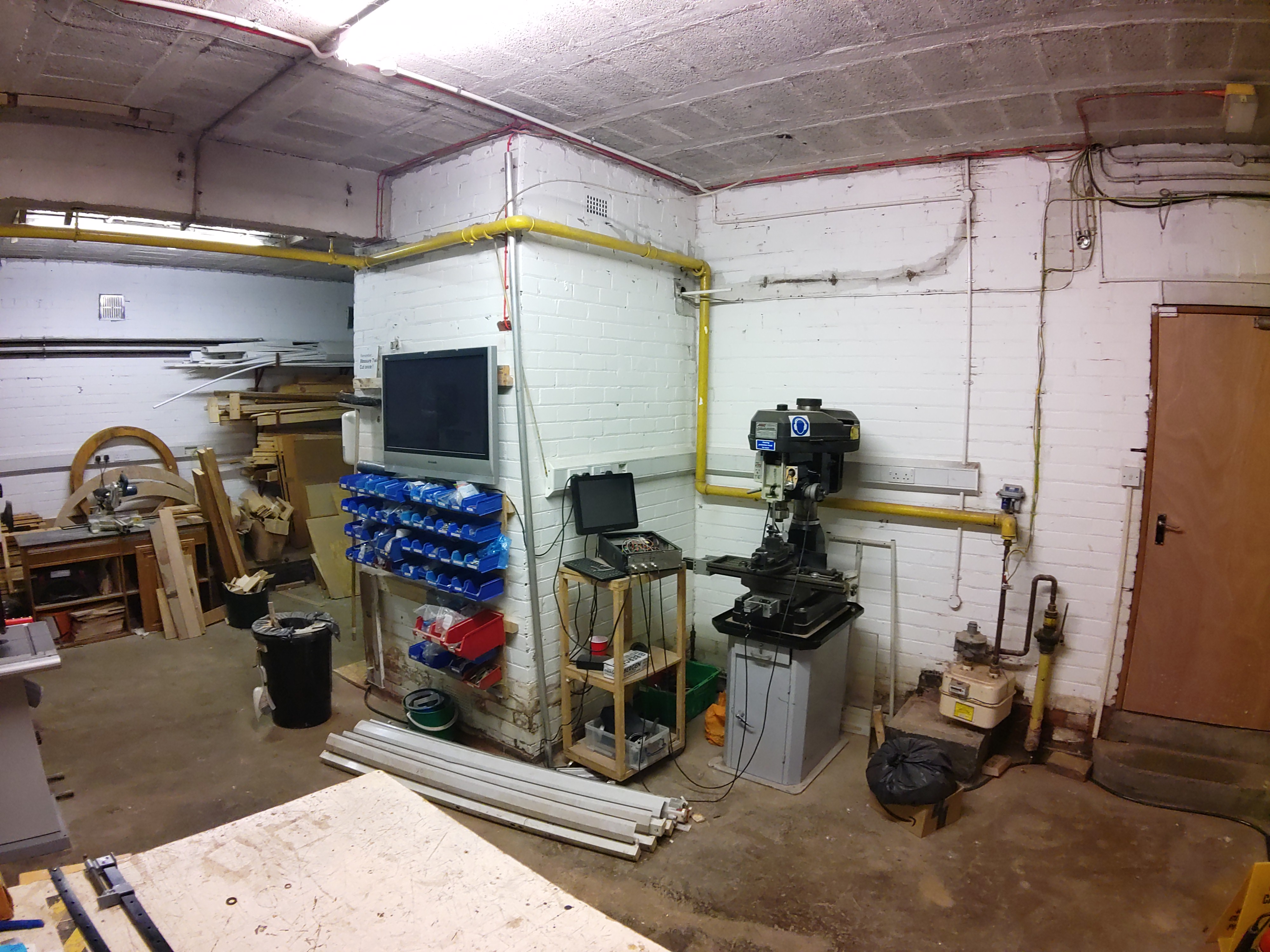

South Basement Workshop

Welcome to this unique and versatile basement workshop. This exceptional space is a haven for woodworking enthusiasts, offering a comprehensive array of tools and equipment to bring your creative visions to life. The workshop boasts a generous floor plan, providing ample room for multiple projects and collaborative work.

Here, we present a non-functioning CNC milling machine, awaiting the touch of a skilled hand to restore it to its former glory. The machine boasts a solid and durable construction, designed to handle heavy-duty tasks once operational.

The plastic bins harbor an orchestra of fasteners. Hex nuts, wing nuts, carriage bolts—they jostle for attention. And the washers? They’re like tiny time-traveling saucers, ready to stabilize your contraptions.

This well-equipped work area is a dream come true for any maker, featuring an impressive array of machine tools designed to bring your projects to life. All tools are maintained to the highest standards, ensuring precision and reliability for every project. The work area is thoughtfully organised, with clear pathways and designated zones for each type of machine, promoting a smooth and efficient workflow.

In the corner you will find our wood and pipe storage area. This dedicated space is designed to cater to the needs of woodworking enthusiasts, ensuring that all materials are stored efficiently and safely. The area boasts a variety of storage solutions, including vertical racks, horizontal shelves, and custom bins, accommodating wood of all sizes and types.

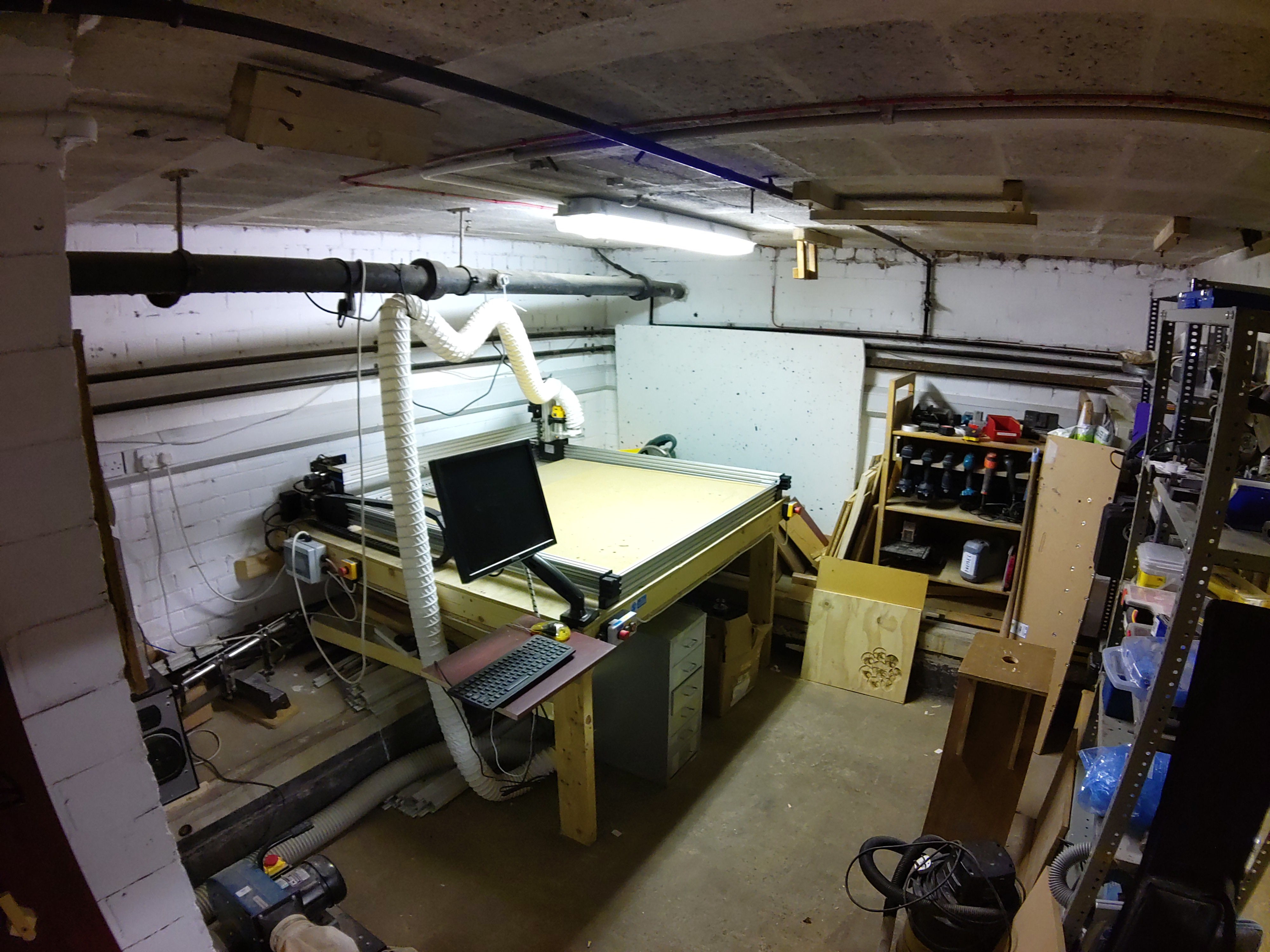

North Basement Workshop

Welcome to the cutting-edge corner of the basement workshop, where innovation meets precision. This dedicated area features the highly sought-after Workbee CNC router, a must-have for any serious maker or woodworker. The Workbee CNC router is the centerpiece of this corner, known for its accuracy and versatility. It’s perfect for intricate carvings, precise cuts, and complex designs. The intuitive control system and software make it accessible for both beginners and experienced users, allowing for seamless operation and creativity.

Welcome to the meticulously curated hand tool collection within our vibrant hackspace. This essential area is a treasure trove for any maker, offering a diverse range of tools that cater to all your crafting and repair needs. Tools are neatly arranged on shelves and in toolboxes, making it easy to find exactly what you need quickly and efficiently. As part of our hackspace, this collection benefits from the collective knowledge and experience of our members, who are always willing to share tips and techniques. Regular maintenance ensures that all tools are kept in optimal condition, ready for use whenever inspiration strikes.

Welcome to the dedicated metalworking area within our innovative hackspace, a haven for metal enthusiasts and craftsmen alike. This well-appointed section is designed to cater to all your metalworking needs, featuring a top-of-the-line metal lathe as its centerpiece. The star of this area is a high-precision metal lathe, perfect for turning, facing, and threading a variety of metals. Its robust construction and advanced features ensure accuracy and reliability for all your projects. Alongside the lathe, you'll find an array of essential metalworking tools, including cutting tools, calipers, micrometers, and more, all meticulously maintained for optimal performance.

Against the rear wall, you will find yet another of our storage areas. These sturdy storage shelves, strategically placed against the wall, are designed to keep your tools and materials neatly arranged and easily accessible.

Against the adjoining wall you will discover the metal stock storage. This dedicated space is designed to cater to the needs of metalworking enthusiasts, ensuring that all materials are stored efficiently and safely. Metals are neatly categorized by type and size, making it easy to locate the exact material you need for your project. Whether you require aluminum, steel, copper, or brass, everything is clearly labeled and accessible. Conveniently located adjacent to the main metalworking area, the metal storage section allows for quick and easy access to materials, streamlining your workflow.

At the center of this dynamic space stands a robust and versatile workbench, designed to be the focal point for all your metalworking projects. This workbench is built to withstand the rigors of heavy-duty metalworking, featuring a solid frame and a thick, durable work surface. Equipped with a high-quality vice, the workbench ensures secure clamping of materials, allowing for precise and stable work.

Using the Space

This section gives an overview of the day to day apsects of using Maker Space.

Member Storage

Member boxes

Each makerspace member is welcome to store their personal equipment/projects in a project box on the Member Shelves. These are situated in the ground floor workshop along the back wall.

You should use a 32 litre 'underbed storage box' with lid, so that it will fit neatly on the shelves. These are available from retailers like B&M (£5 or 2 for £8 as of 06/2025).

Larger items

We recognise from time to time people might need to temporarily have larger project items in the space when they are being worked on.

If you think this applies to you, you should ask via one of the communications channels before bringing in any project that doesn't fit in your member storage box.

3D Printer Filament

Maker Space has a stock of filament that may be used for printing in the space.

The Maker Space filament stock

Any filament in the following locations is to be considered part of the Maker Space filament stock:

- in the cardboard box under the desk with the Bambu Lab printers on

- loaded in the AMS of either Bambu Lab printer (when no job is running)

- loaded in the external filament spool on Kirisame (when no job is running)

- loaded in the Prusa Mk3 or on its spool holder (when no job is running)

The current price for filament from the Maker Space stock is £0.012 per gram.

Accounting

- Your filament consumption should be taken from the estimation made by the appropriate slicer

- Should a print fail, you should pay the best approximation possible of the consumed filament

- There is not currently any centralised recording of print jobs, you are expected to do your own accounting of your consumption

- Payments to the space should be clearly indicated that they are for filament

Donating filament

Members may donate filament to the Maker Space filament stock, in which case the following rules apply:

- the filament must be suitable for use in the Maker Space printers and its material clearly identified

- the member who donated the filament may use it at zero cost

- all other members may use it, and pay the above rate to do so

Personal filament

Members may use their own filament in the Maker Space printers, in which case the following rules apply:

- filament should be unloaded when printing is complete

- filament should be kept in the member's storage box or brought in as required (i.e. not left somewhere where it would be assumed to be part of the Maker Space stock)

Hack or Die

In the ground floor corridor there are a set of blue shelves; this is the hack or die. A treasure trove of random stuff looking for a new home.

Anything that is unwanted, yet not obviously rubbish can be placed here.

Anyone who would like the item, for whatever reason, may take it. Once an item has been taken, it cannot be returned, it is now yours.

Anything that has not been claimed in a reasonable amount of time (around a few weeks) should be disposed of appropriately.

Waste Streams

We produce some waste in Maker Space, this needs to be removed to keep the space tidy. The building does not have a commercial waste collection, so waste must be removed by members.

Disposal streams

General waste

There are several general waste bins throughout the space. Unless a bin is labelled otherwise, assume it is for general waste.

Anything placed in these bins will likely end up in landfill.

Common recycling

There are recycling bins near the door to the goldfish bowl in the main space. These are clearly labelled. Please READ THE LABELS, and put things in the correct state in the correct bins.

Wood

There is a box on the floor to the left of the laser cutter for wood waste. This is taken to a recycling centre and likely ends up in an incinerator.

Use this for scraps that are likely to no longer be of use.

E-waste

There is a box on the floor near to the common recycling bins in the main workshop. This is taken to a recycling centre and might be recycled to some extent, maybe.

This may be used for small items of e-waste created in the space. If you would otherwise throw stuff in general waste you may bring things in to be correctly disposed of if you are not able to take them to an appropriate recycling centre yourself (but do not take the piss).

PLA

There is a red sweet box on the 3D printing station where scraps of PLA can be deposited and shipped away for recycling. Ensure only PLA goes into this container.

You may also drop unwanted or failed PLA prints into this box.

Batteries

There is a small tub near the common recycling bins that expired single use batteries can be left in. Should this tub be full, please take the contents to Tesco (or your major supermarket of choice) where they should have a bin to recycle them.

Other batteries (i.e. those you cannot take to a supermakret) should be taken home and disposed of yourself.

Anything else?

Anything not explicitly listed above that needs to be disposed of must be taken out of the space by whoever created the waste.

Reuse streams

Wood

There are several bins in the south basement workshop for wood scraps.

They are for scraps that may be of use for shims, sacrificial parts/supports, push sticks, paint stirrers, etc.

Please be reasonable about what will actually be useful, keep only things that have a realistic chance of being used and place other scraps in the wood disposal bin.

Laser suitable materials

There is a large box on the table next to the laser cutter where material offcuts that may still be of some use may be left.

Suitable scraps include:

- small sections which may be used for inductions

- moderately sized sections which may be enough for small jobs

- unusual materials that others may want to try before committing to purchasing

Again, be realistic about what is useful. Anything smaller than 40mm in any dimension is unlikely to be used (unless it is an unusual material).

Communications

There are various ways to communicate with members and the wider maker community, including the following:

Instant Messenger

Our IM platform of choice is Matrix.

How to join

A simple guide:

For a web based Matrix client (requiring no installation or anything else), go to:

If you want to download a client (optional), there are clients for android, IOS, linux, windows and easiest of all, browser only version, which is probably ideal for trying out for the first time here:

https://matrix.org/docs/projects/try-matrix-now/

If you are new to Matrix, and using Element in a web browser...

- Create an Account

- Sign in

- Follow the matrix.to link for our space here

- Join the space and any rooms that you may be interested in

Maker Space Member list

There is a members list all members are subscribed to during the sign up process. Ask if you are a member and have not already been added.

It is used to discuss around, make decisions about the space operation and notify of updates to machine maintenance and the space in general. As a member, you are expected to keep an eye on emails on this list as they may contain important information about the space.

Please Note: Emails to this list are vetted. Please do not attempt to send marketing material to this list.

North-East-Makers list

This is a list for the wider community, not just Maker Space members. North-East-Makers List for discussing anything related to making.

Please Note: Emails to this list are vetted. Please do not attempt to send marketing material to this list.

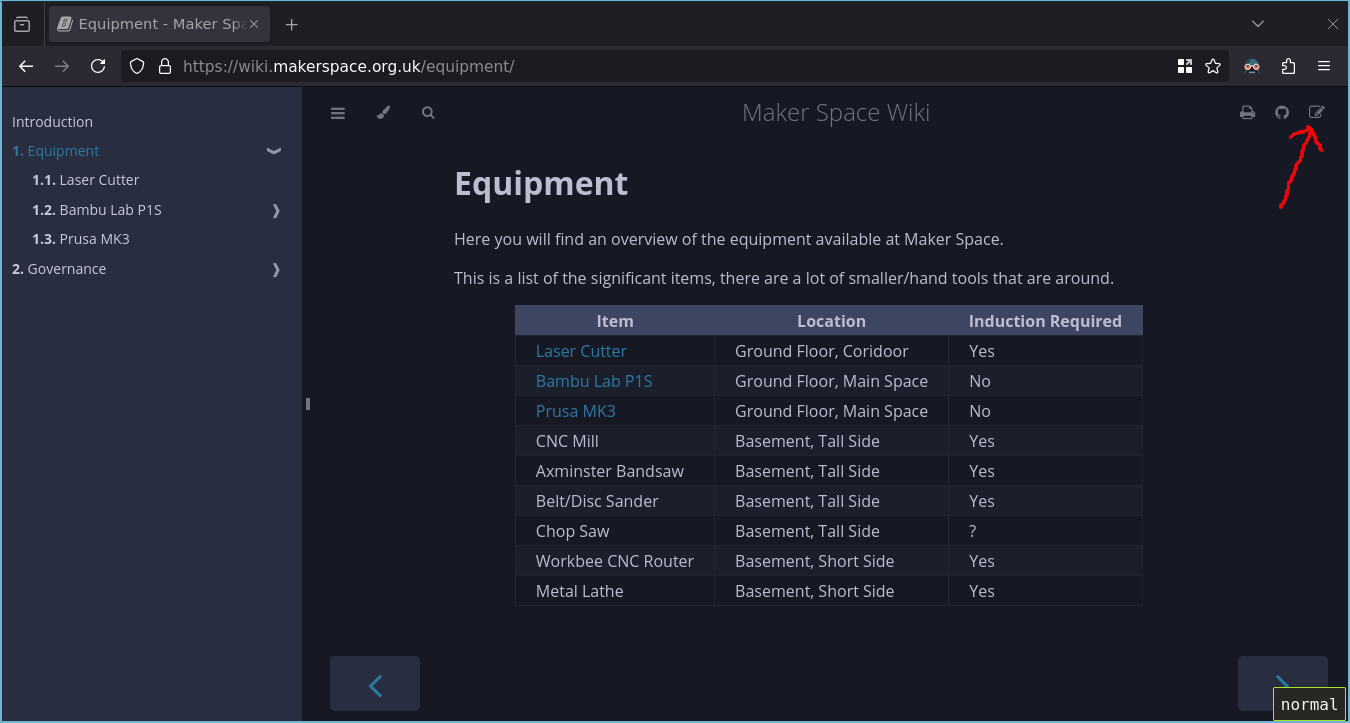

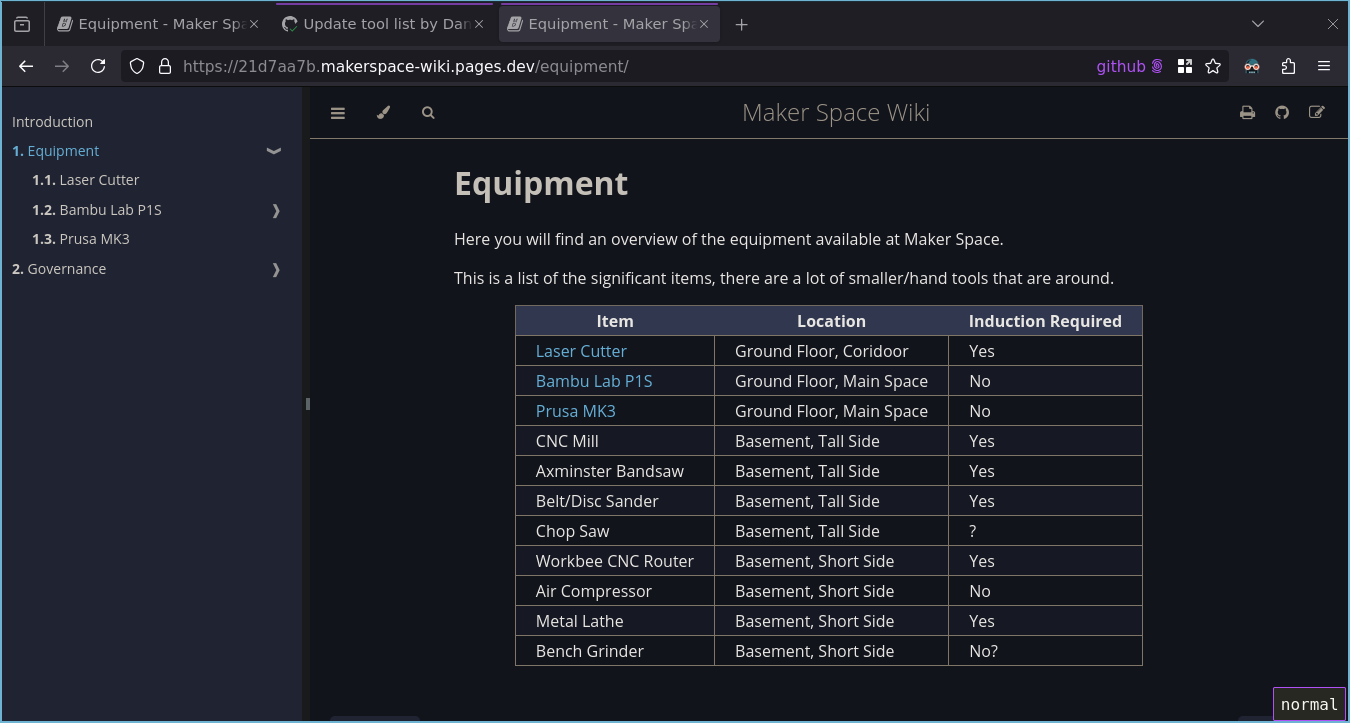

Equipment

Here you will find an overview of the equipment available at Maker Space.

Larger, more complex or more significant items are listed, by area, below. A more complete, yet with less information, list of things we have can be found here.

Equipment is typically listed with a list of responsible person(s). These people are who you should seek advice of with regards to induction requests, reporting faults and discussing alteration/upgrades. Do not attempt to modify or repair a piece of equipment without prior discussion/approval/understanding of the people responsible for the equipment in question.

Access controlled equipment

Certain items in the space are fitted with RFID access controllers. These ensure that only members who are sure of their own competence in using a specific piece of equipment can use them.

In order to gain access to a piece of equipment, a responsible person for that machine will have to verify that you are sure of how to operate the equipment safely. More information about the skills and knowledge you will be required to demonstrate can be found on the page for that machine.

Ground Floor Corridor

Ground Floor Workshop

South Basement Workshop

North Basement Workshop

Abridged Equipment List

This list serves as a more complete list of the things we have in Maker Space. It does, however, contain much less information than the pages for specific pieces of equiptment.

Some items on this may be deserving of a full equipment page. If you believe that to be the case for a particular item: well volunteered.

| Item | Approximate Location |

|---|---|

| Henry hoover | Ground Floor Workshop |

| EEPROM programmer | Ground Floor Workshop - goldfish bowl - right hand shelves |

| Spare monitors | Ground Floor Workshop - goldfish bowl - right hand shelves |

| Bench power supplies | Ground Floor Workshop - goldfish bowl - right hand shelves |

| More bench power supplies | Ground Floor Workshop - solder station |

| Even more bench power supplies | Ground Floor Workshop - goldfish bowl - right hand shelves |

| USB microscope | Ground Floor Workshop - goldfish bowl - right hand shelves |

| Various network switches | Ground Floor Workshop - goldfish bowl - right hand shelves |

| Rigol oscilloscope | Ground Floor Workshop - goldfish bowl - right hand shelves |

| Label printer | Ground Floor Workshop - goldfish bowl - middle drawer under 2D printer |

Laser Cutter (Hoshiguma)

A laser cutter. It cuts stuff using a laser.

It has an 80W CO2 laser and a bed with a usable area of 580x380mm.

Essential Information

- Location: Ground Floor Corridor

- Responsible Person(s): Dan Nixon

- Induction Required: Yes

Usage notes

It is not permitted under any circumstances to leave this machine running unattended!

A list of compatible materials can be found here. A list of known good settings is available on the sheet next to the computer.

The currently fitten lens (F=50.8mm) should be good for cutting material up to ~10mm. If you want to try and cut something thicker, we do have other lenses. Ask Dan if you have a reason to need this.

To the left of the machine there is a small table. This can be used for material preparation, finishing and sorting of machined pieces. If you have machined anything particularly smelly, as a courtesy to other members, please do your finishing/sorting on this table and do not bring it into the main workshop.

In front of the machine/around the corner, on the black table is a waste bin for scraps that are no longer wanted but still potentially useful along with some 6mm birth plywood that is available to use. On the floor underneath this table is a bin for waste wood scraps that are not feasibly useful any longer. See waste streams for more details.

Troubleshooting

If any of the following happen, immediately stop using the machine, turn off both switched sockets on the wall behind/in between the machine and the cooler unit and let Dan know:

- illuminates all three status lamps at once

- leaks cooling water

- a collision involving a moving part of the machine

Induction checklist

- Turning on machine with fob, requirement for empty bed, emergency stop

- the requirement to operate emergency stop when sustained fire occurs

- Panel controls

- X/Y/Z axis motion

- motion mode (central d-pad button)

- pause/resume

- stop

- pulse

- escape

- fume extraction mode

- Note the fact that no other panel controls should be required under normal operation

- General PC use, mention that LightBurn is also available on the CAD PC

- LightBurn

- loading files

- assigning layers

- setting layer mode, speed, power, etc.

- layer order

- preview

- origin selection/settings

- frame

- Workpiece alignment and focusing

- Start/during/end of job processes, the requirement to attend the machine

- Turning off machine and PC

- Available materials and waste streams in vicinity of machine

- The need to keep the machine tidy

Statistics

For those who are curious, the following dashboards are available to show telemetry data from the laser cutter:

Laser suitable materials

Materials that can be cut/engraved (largely taken from the London Hack Space wiki).

If you want to cut a material which is not on the allowed list you must contact the maintainers through the members email list to ask permission.

Prohibited materials

- Anything that cannot, with reasonable confidence, be identified

- Cork (fire risk)

- Wood which isn't explicitly laser-grade (laser contamination, fire risk, emissions)

- Food (laser contamination, fire risk, emissions)

- Body parts

- Plastics containing PVC (laser contamination, emissions)

- Plastics containing ABS (laser contamination, fire risk, cyanide emission)

- Fibreglass (laser contamination, fire risk, emissions)

- Circuit boards (laser contamination, fire risk, emissions)

- Polycarbonate (laser contamination, fire risk)

- All metal (except engraving anodized aluminium)

- Polystyrene (laser contamination, fire risk, emissions)

- Polypropylene (laser contamination, fire risk, emissions)

- HDPE (high-density polyethylene or polyethylene) (laser contamination, fire risk, emissions)

- Carbon fibre (laser contamination, fire risk, emissions)

- Shuttering ply (laser contamination, fire risk, emissions)

- Latex (laser contamination, fire risk, emissions)

- Leather, all. (laser contamination)

- Anything not explicitly allowed (either in the lists below, or by prior permission)

Allowed

Woods:

- Laser-grade MDF (max 8mm)

- Laser-grade plywood

- Birch ply (max 9mm)

- Poplar ply (max 9mm)

- Balsa wood

- Paper (cutting only)

- Card/Cardboard (cutting only)

Plastics:

- Thin Polypropylene sheet (<1mm)

- Acrylic (max 10mm)

- Foamcore (non-PVC variety)

- Correx (Genuine non PVC)

- Depron foam (Fire risk, must be closely monitored)

- EVA Foam (if real)

- Delrin (max 8mm)

Textiles:

- Cloth/felt/hemp/cotton (Not plastic-impregnated fabric)

- Polar Fleece

Engraving only

- Stone

- Ceramic tile

- Non-resinous wood IE hardwood

- Glass

- Anodised Aluminium

Setting up LightBurn on your own laptop

It is possible to use your own laptop for preparing jobs, however the PC next to the machine must always be used for running the machine. To do so, you will need LightBurn installed and licensed and the configuration for the laser cutter installed.

Process

It is assumed that you have not previously installed LightBurn on the target laptop. If you have then you more than likely do not need this guide, can download the device profile file from step 2 and go on your merry way.

- Install LightBurn from here.

- Download

device_profile.lbdev. - Launch LightBurn.

- Either activate the trial or purchase your own suitable license and activate that (see note below).

- When prompted to add a machine, import the file downloaded in step 2.

- You should now have a machine named Hoshiguma available, use this when you want to prepare or machine jobs on this laser.

License requirement

Hoshiguma uses a Ruida controller, so is therefore a DSP machine in the eyes of LightBurn.

You will need either a DSP or DSP + Galvo license, or purchase the DSP addon. If you are purchasing a license with the discount code (see below), you should purchase a DSP license.

LightBurn discount

We (Maker Space) have a code for discounted Light Burn licenses for members. If you would like one, ask the person who did your laser training.

Note that the license is only to be using with the laser cutter in Maker Space. Should you need to use other machines you should pay for a full license.

Bambu Lab P1S

Two Bambu Lab P1Ses, Hakurei and Kirisame. Very good, fast FDM 3D printers.

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): Dan Nixon

- Induction Required: Yes

- Build volume: 256mm x 256mm x 256mm

| Printer | Nozzle size | LAN access code | Filament Options |

|---|---|---|---|

| Hakurei | 0.4mm | 22497498 | AMS compatible spools only |

| Kirisame | 0.4mm | 29623040 | AMS compatible spools or up to 3 Kg spools via top spool caddy |

Usage notes

It is not permitted to leave this (or any other) 3D printer running whilst Maker Space is unoccupied!

3D printer filament supplied by Maker Space must be paid for. See 3D Printer Filament for details.

Useful links

Induction checklist

- General info

- Filament availability, compatible filaments, price for Maker Space filament, options for using own filament

- The requirement to not leave the machine running unattended

- Do not remove the memory cards unless you want to get timelapse footage

- Start up procedure

- Power switch location

- Verify no obstacles inside printer

- Bambu Studio

- Initial setup (if appropriate)

- Adding our printers (use codes above, not the printer menu)

- Configuring a basic print job

- The requirement to ensure the AMS is synchronised

- Filament loading

- General filament handling, storage, the requirement to secure the loose end

- Loading via the AMS

- Loading vis the external spool

- Start of job

- The ability to skip full bed levelling

- Build plate cleaning

- Check for correct build plate seating

- The requirement to observe the start of job and first layer

- Fault handling

- Where to see fault codes in Bambu Studio

- The requirement to not attempt to maintain the printer

- End of job

- Removal of parts from bed

- Ensure printer is left clean, serviceable and powered off

Prusa MK3

A sort of OK FDM 3D printer.

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): ?

- Induction Required: No

- Nozzle size: 0.4mm

Usage notes

It is not permitted to leave this (or any other) 3D printer running whilst Maker Space is unoccupied!

3D printer filemant supplied by Maker Space must be paid for. See 3D Printer Filament for details.

Octoprint is installed on a Raspberry Pi, which is capable of controlling and monitoring the printer over the network. The IP address to access the Octoprint interface is on a label on the front of the printer.

If you'd rather print from the SD card, you might find it useful to create a folder with your name for your files. Please remove any big files once you're done with them to save clogging the card up (same goes for Octoprint).

PrusaSlicer is generally the most straightforward way of slicing your files for printing, as it has a pre-made and tuned profile for the MK3.

If you don't know how to use a 3D printer, or if you're unsure of how to use the specific one in the space, please do ask someone before attempting to.

Duratool Desolder Station

The Desolder Station is mainly for desoldering through hole components. It is particularly great at removing solder from plated through holes where the copper track is on both sides of the board and the hole itself is also metal.

It may have other uses, but no it is not designed to suck anything but solder. It is also not that ideal for surface mount, as the components can end up heat damaged or sucked up and jammed inside the nozzle!

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): Jon Davies

- Induction Required: No

How to use the tool

- Press the red power button on the front of the base

- Set the 'C/F' temperature mode to Celsius

- Start with a temperature setting of 350c (The iron will take a few minutes to get up to temperature - be patient) :)

- Place the hole of the iron over the joint to be desoldered

- Hold the iron still for two seconds (until the solder begins to melt)

- Waggle the iron side to side for two seconds (to thoroughly melt the solder)

- Press the trigger and continue to waggle for a further second (The air pump activates and draws away the solder)

- Remove the iron from the solder joint (Solder has now gone)

- Repeat steps 4 to 8 for several solder jionts

- Clean the iron tip in the tip-cleaning brass (Do this regularly to keep a clean healthy tip and a good thermal interface)

- Repeat steps 4 to 10 for your session

- Clean the tip one final time

- Stow the iron in the holder

- Turn off the power

Troubleshooting & Tips

Solder slow to melt (more than five seconds)

- For larger components, it may be necessary to increase the temperature to 375c.

- For ground planes, it may be necessary to increase the temperature to 400c

Loss of Suction

The filter in the iron/base has become clogged.

- Stop using the desoldering tool

- Stick a notice on the base to indicate the tool is in need of TLC

- Notify a maintainer

I am experienced and impatient!

Ok... you can speed up your desoldering session with an increased risk of component damage. Increase the temperature to 400c but work fast on large components and really fast on small components.

kWeld spot welder

The KWeld spot welder is ideal for welding up Lithium Ion Batteries (eg 18650) cells into battery packs.

Makerspace has the full mains powered version (donated by David Pye). It consists of the KWeld device, the kSupply PSU adaptor and the KCap supercapacitor bank to provide the power for spot welding.

It is capable of spot welding up to 0.3mm Nickel strips.

The space has a small amount of 0.2mm nickel strip, some spot-weldable battery tags as well as the paper discs to be fitted under 18650 cell ends to reduce the shorting risk when packs are assembled.

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): David Pye

- Induction Required: Yes

Safety information

- Welding Li cells can cause fire - LiIon cells can combust if shorted or if damaged

- If you are not sure what you are doing, please get supervision/advice before using

- RTFM (read the manual) - link below in the Useful links section, before using the device

- Device generates very strong magnetic fields when welding. Do not use if you have a cardiac pacemaker or other implanted medical devices

- Use an appropriate pulse strength (in J) for what you are welding - be aware that LiIon batteries can explode if damaged

- Take safety precautions - eg bucket of sand nearby in case a battery becomes damaged and causes a fire

Useful links

kWeld user manual - PLEASE READ ME BEFORE USING DEVICE

kCap user manual - for troubleshooting

kSupply user manual - for troubleshooting

CNC Mill

TODO

Essential Information

- Location: South Basement Workshop

- Responsible Person(s): David Pye

- Induction Required: Yes

Axminster Bandsaw

An Axminster SBW4300B bandsaw.

Essential Information

- Location: South Basement Workshop

- Responsible Person(s): Ben Shaw, Dan Nixon

- Induction Required: Yes

Usage notes

The manual for this machine can be found here.

You will be expected to demonstrate the following competencies before gaining RFID access to this machine:

- Understand how the electronic brake operates and the need to let it do its thing after hitting stop.

- Have an appreciation for appropriate (goggles, hearing protection) and inappropriate (gloves) PPE when using the bandsaw.

- Know how to move the fence and change its orientation.

- Understand how to adjust the blade guides and the importance of not having them higher than necessary.

- Know how to stand when using the bandsaw (i.e. not leaning into it).

- Know to never be pushing material with your hand in line with the blade - always to the side, use a push stick etc.

- Understand appropriate materials to cut on the bandsaw - and inappropriate ones. Appreciate how to handle different materials (e.g. wear a mask for MDF and other dusty things).

- Know the appropriate types of cut which can be made on the bandsaw (OK for reasonably thick, reasonably long cuts, bad for tight corners - use the scroll saw).

- Understand the need to keep the blade tensioned, and know how to adjust the tension.

- Understand how and why to use the cross-cut sled (prevents binding on the fence when cross-cutting).

- Know to not start/stop the machine with the workpiece in contact with the blade.

- Understand how to cut thin materials - use a sacrificial board below to prevent tear-out.

- Know how to use dust/chip extraction when necessary.

Record Power Drill Press

A Record Power DP58P floor standing drill press.

Essential Information

- Location: South Basement Workshop

- Responsible Person(s): Dan Nixon

- Induction Required: Yes

Usage notes

The manual for this machine can be found here.

You will be expected to demonstrate the following competencies before gaining RFID access to this machine:

- Understand the need for protective eyewear for operator and observers.

- Understand the need to protect byestanders.

- Be aware of the risks of wearing gloves while operating the pillar drill.

- Be able to change a drill bit.

- Understand what the guard is and the importance of using it (and that it disables the machine when flipped up).

- Be able to adjust table height and secure it.

- Understand the need for appropriate work holding (and scrap board underneath the work to avoid drilling the table etc.).

- Be able to use the depth stop .

- Be able to change belt speeds.

- Understand the need for different drill speeds.

- Understand the need to leave the drill in a safe and clean state for the next user.

A useful speed chart can be found here.

Record Power Belt & Disc Sander

A Record Power BDS250 belt and disc sander.

Essential Information

- Location: South Basement Workshop

- Responsible Person(s): Iain Yarnall, Dan Nixon

- Induction Required: Yes

Usage notes

The manual for this machine can be found here.

You will be expected to demonstrate the following competencies before gaining RFID access to this machine:

- Understand the need for protective eyewear for operator and observers.

- Understand the need to protect byestanders.

- Understand the safety implications of the belt and disc being linked.

- Be able to employ methods to prolong the life of the belt and disc.

- Understand which side of disc sander is safe to use.

- Be able to use the mitre fence on the disc sander.

- Understand how different parts of the belt can be used.

- Change orientation of the belt sander between horizontal and vertical.

- Adjust the tracking of the belt sander.

- Be able to clean the belt and disc.

- Understand the need to leave the sander in a safe and clean state for the next user.

- Understand the need to inform members and the maintainer if you consider the tool to be unusable/damaged or faulty.

Spare Parts

-

250mm Self Adhesive Sanding Discs: e.g. https://www.axminstertools.com/proxxon-self-adhesive-sanding-disc-250mm-80grit-ptk-5-477029

-

150mm x 1,220mm Sanding Belt: e.g. https://www.axminstertools.com/hermes-abrasive-belt-150-x-1-220mm-x-80-grit-110224

-

Belt Cleaner: e.g. https://www.axminstertools.com/axminster-abrasive-belt-cleaner-standard-210-x-40-x-40-310398

Makita Chop Saw

TODO

Essential Information

- Location: South Basement Workshop

- Responsible Person(s): Iain Yarnall

- Induction Required: No?

Workbee CNC Router

The WorkBee is a CNC milling machine that can cut, carve, and engrave. It's a self-build machine using readily available parts like extruded aluminium rails, and a standard DeWalt Router, along with bespoke controller hardware and software.

Essential Information

- Location: North Basement Workshop

- Responsible Person(s): David Pye, David Papadopoulos, Tim Poolan

- Induction Required: Yes

Specifications

Kit

Ooznest WorkBee Z1+, consisting of mechanical elements:

- 1500x1500mm frame (Working Area: 1270x1270mm)

- Router Mount - DeWalt - 69mm

- CNC Dust Shoe

- Touch probe (https://learn.ooznest.co.uk/Guide/First+Project/243)

- Surfacing tool

Router

Dewalt Router D26200 Type 1 (2018)

Speed selection

| Dial Setting | Approximate RPM |

|---|---|

| 1 | 16000 |

| 2 | 18200 |

| 3 | 20400 |

| 4 | 22600 |

| 5 | 24800 |

| 6 | 27000 |

1-3 are appropriate for large diameter cutters, 4-6 are appropriate for small diameter cutters, softwoods, plastics and laminates.

Controller

WorkBee Control

What it can do

Workable materials

- Foams

- Plastics

- Wood

- Carbon Fibre

- Aluminium

Cutting feeds, speed, and depth

- 44mm maximum cut depth

- DeWalt spindle speed max 27,000 RPM, manually controlled by thumbwheel

- feed speed 0 to 5 millimeters per second

Essential Operation & Configuration Points

Main power (computer and controller)

Switch at the wall and 3 around the bed, including one next to the spindle power switches.

Spindle power

Switch on router and at front left corner of the bed.

Dust extraction power

Switch out the wall and on the blower itself.

Job calibration

This is about defining a workpath start point in relation to one corner of the extruded travel frame. It must be done at the start of every job. It involves homing the spindle at the rear right corner of the bed and then at a specific start point somewhere within the bed, usually near the front left corner. It is accomplished through the WorkBee GUI dashboard.

Plinth & frame alignment

This is an occasional check to ensure that the extruded gantry frame is square and level in relation to the basement floor. It needs to be checked periodically and if something is out of true, it needs to be adjusted by the maintainers.

Gantry speed (Feed Rate)

A given cutting tool (e.g. endmill) can be driven at different speeds depending on the material it is cutting. The speed of driving is often called the feed rate. In our case, the feed rate is the combined horizontal and vertical speed of the gantry. The movement of the DeWalt router is controlled by the WorkBee software, either according to a preprogrammed workpath, or manually via the Workee Dashboard.

The main factors in identifying suitable feed rates are a ratio of material, cutting faces, and spindle speed.

FR = RPM * T * CL

Where:

- FR = the calculated feed rate in inches or mm per minute.

- RPM = is the spindle speed of the router.

- T = Number of teeth on the cutter.

- CL = The chip load or feed per tooth. This is the size of chip that each tooth of the cutter takes.

Of these, Chip Load requires more careful consideration. Each type of material is associated with a range of chip loads. Foam and wood are generally lowest in the ranking of chip loads. Most tools datasheets specify a chip load assuming a depth of cut (DOC) equal to the tool diameter.2

RPM = FR/(T * CL)

Essential Competencies

- Router bits & collets appropriate for the task

- Material securing

- Understanding & working within tolerances

- Workpath design

Resources

- WorkBee setup and user guides here: https://learn.ooznest.co.uk/c/Original_WorkBee_Z1_Plus__Assembly_Manual

- Scrap wood in the South Basement

- 3-face clamp for curved/irregular shape pieces of working stock

Status

2024.10 Currently using improvised wasteboards. There are a pair of MDF boards that nearly span the bed, but they are warped, by as much as 6mm across the width. Warping may be due in part to basement humidity, and while there are water-resistant wasteboard materials available, we have not seen a use case for a full size sheet. For the time being, we are making smaller wasteboards to suit the jobs we're doing. Software File transfer

Potential improvements

- GCode viewer

- https://learn.ooznest.co.uk/Guide/WorkBee+Control+Overview/22 Step 7

- https://learn.ooznest.co.uk/Guide/First+Project/243 Step 10

Metal Lathe

We have a small "Model Engineers" style lathe generically known as a 9x20 (swing x length between centres). It is capable of good work but as with many lathes in this class the lack of rigidity makes it prone to chatter if your cutting speed and/or tool sharpness isn't spot on.

Although classed as "Metal Turning" lathe it can be used to turn plastics and wood (making dowels out of scrap wood or plastic inserts/wheels are a couple of non metallic possibilities).

Essential Information

- Location: North Basement Workshop

- Responsible Person(s): Malcolm G

- Induction Required: Yes

Resources

The manual for this machine can be found here.

A guide to replacing the bearings can be found here.

Ongoing Refurbishment

The lathe was acquired second hand and as such is been subject to semi continuous refurbishment although it is left in a usable condition whenever possible. Maintenance completed to date includes:

- Addition of guard

- Headstock rebuild and bearing lubrication

- Tailstock rebuild

- Saddle/slide rebuild and adjustment of gib strips

- Tool rack

- provision of general use set of tools

- addition of magnetic base to dial indicator to enable centring of work in the 4 jaw chuck

- Refurb/balancing of large grinder to facilitate lathe tool sharpening (see separate article on bench grinders)

- Replacement of idler and intermediate pulley bearings

- Motor aligned so that toothed belt stays in position and low speeds are available

- Replacement of custom electrics with a standard NVR/stop switch

Remaining issues:

- the mounting table lacks rigidity and it is suspected mounting on a solid block (e.g. paving slab) might reduce chatter

- procurement of a fractional horsepower 3 phase motor would allow installation of a variable speed drive with added advantage of faster stopping time

- fabrication of jig to enable sharing of boring tools from the milling machine (one exists but is the wrong diameter)

Possible enhancements (only if there is a critical mass of interest)

- Addition of a headstock shaft encoder and stepper motor drive to the lead screw would allow flexible screw cutting

- Digital Read Out (DRO) on bed and cross slide

Essential Skills

Ideally we need to establish a larger core of members who are both competent and confident in the use of the lathe including essential skills:

- Understanding how to work safely and avoid danger

- Understanding the limits of the lathe and how to look after it

- Understanding the most common machining techniques

Typical techniques most people will need to know would include:

- methods of mounting materials (chuck types / faceplate use)

- drilling (including use of centre holes)

- use of tail stock centre for longer jobs

- appreciation of cutting speeds

- tool selection / sharpening

- typical cuts (e.g. facing / boring etc)

Spare Parts

- Toothed Belt 170XL050: e.g. https://simplybearings.co.uk/shop/p670999/170XL050-Major-Brand-Synchronous-Toothed-Belt-0.50-inch-Wide-17-inch-Length-85-Teeth/product_info.html

Large Bench Grinder

This is a medium size grinder with coarse and fine wheels.

It previously suffered from excessive vibration which has been largely solved by truing the wheel flanges and dressing both wheels

It is suitable for sharpening lathe tools and other steel tools.

Please DO NOT attempt to grind soft metals such as alloy, wood etc as this clogs the carborundum structure and can damage the wheels.

Also DO NOT routinely grind on the side of the wheels as this can lead to damage and potentially lead to a burst wheel (the only exception is the sharpening of twist drills using the drill sharpening jig).

Essential Information

- Location: North Basement Workshop

- Responsible Person(s): Malcolm G

- Induction Required: No?

Water

Sharpening / Grinding tools makes them hot and you will likely find a small "cup" of water near the grinder for dipping hot tools into.

Lathe tools can be abused somewhat, particularly when fashioning solid High Speed Steel into a tool but it is still good to dip them into water before they glow red.

Carbon steels such as screwdrivers and wood chisels require extra care with only the lightest of grinding between cooling in the water pot (this requires skill so please seek assistance).

Basic competencies for grinder use

- Appreciation of the criticality of using correct eye protection.

- Understanding of the types of material and/or tools which may be ground and temperatures.

- Understanding how to check wheels for signs of damage before use and which wheel surface to use.

Potential improvements

- Sturdier tool rests (the existing ones are very lightweight and the coarse wheel one has an annoying vee slot).

- Refurb of acrylic guards (these are somewhat opaque).

- Procurement of a wheel dressing tool.

Large Air Compressor

TODO

Essential Information

- Location: North Basement Workshop

- Responsible Person(s): Malcolm G

- Induction Required: No

Infrastructure

The things that make Maker Space usable.

- Networking

- RFID access controllers

- Hot water dispenser

- DeLonghi Magnifica coffee machine

- Vending machine

- Main Workshop Air Exchange

- Basement Workshop Air filtration

- Music server

- Wiki

RFID Access Controllers

This page contains a brief run-down of the RFID access controller used to control the members door entry system as well as expensive, or hazardous machinery.

Essential Information

- Responsible Person(s): David Pye

User instructions

| LED colour | Meaning | Notes |

|---|---|---|

| Blue | Idle | Associated device is locked and the access controller is waiting for a tag to be presented. |

| Yellow | Verifying | Presented tag is being checked against an updated allowlist. |

| Green | Allowed | Presented tag was on the allowlist and the associated device is unlocked. Remember to log out once you are finished with the machine by presenting your tag again. |

| Red | Denied | Presented tag was not on the allowlist and the associated device remains locked. |

| Magenta | Offline | Controller has no network access and is running in offline mode. Cached tags will still unlock the associated device. |

Note: If you present an RFID that isn't known to the controller, the LED will briefly go yellow - it checks with the backend server that the database is up to date (ie has this RFID just been added to the list of valid users?) then either green or red, depending on the result.

If the controller appears to remain blue when an RFID is presented, this is most likely because it cannot read it - those small RFID jewellery rings are sometimes prone to this, as the RFID reader boards aren't always sensitive enough to pick them up.

For access to the door, this should be covered in your member induction, otherwise mention it to whoever did your induction. For access to machinery, this is handled when you receive your induction on the machine in question.

Note: The access controllers are part of the space infrastructure. Hacking them (especially to gain access to a tool you are not permitted to use) will be viewed very seriously, and may result in sanctions.

Technical details

- The controller is powered from a Chinese/Ebay 240v->5VDC (isolated - allegedly...!) power module.

- The main 'brain' is an ESP8266 (ESP-12) board, mounted to a custom-designed PCB, containing a 5v->3v3 linear voltage regulator, jumper for run/program mode, FET for triggering a relay, and several rows of pins for connections.

- RFID reader - MFRC522 RFID reader board for reading MiFare NFC cards or similar

- SSR - the access controllers are using Fotek SSRs (nominally rated at 40a, but their pedigree is questionable and they may not actually be able to run at this full rated current)

- LED - a 'NeoPixel' addressable LED for status updates

Sequence of events

Init:

- Controller powers up, connects to backend server.

- Checks its' flash-held database is in sync with the online copy by checking it's MD5 hash with the MD5 hash of the current server copy. This is done using the HTTP/1.1 ETag function. If the hashes are the same, the databases are in sync.

- If not the LED will remain yellow, the remote database is downloaded, and programmed into flash on the controller.

- The LED will then go blue waiting for an RFID card to be presented.

Valid card (known to local db);

- SSR enabled. LED to green. MQTT message broadcast to MQTTPi in space. Log message sent to backend server.

Possible invalid card: (not in local db):

- Quick check again to see if DB up to date. If not, download remote DB, program to flash and then check again.

- If card now in database, proceed as above. If not, pause few seconds with red LED shown (denied) then proceed to blue awaiting a valid RFID to be presented.

Logout:

- When the LED is green (ie device unlocked), ANY rfid will lock it and sign out the current user.

- SSR off, LED->blue for resting state, MQTT message and remote log message is sent.

Main Workshop Air Exchange

There is an air extraction fan for the main space fitted above the front door. The control for it is located in the south west corder of the ground floor main workshop. It is recommended to open a window in the goldfish bowl when this fan is in use to enable the most effective air exchange throughout the main workshop.

This fan can be used to maintain the main workshop at a comfortable balance of temperature and air quality.

Basement Workshop Air Filtration

Both the north and south basement workshops have Axminster air particle filters. These are suitable for removing the worst of suspended dust from the air.

They are not helpful for very fine or hazardous dust/particles/fibres (i.e. anything you would usually use a HEPA filter or class H vacuum for).

Essential Information

- Responsible Person(s): Dan Nixon

Instructions for use

If the air quality feels a bit shit, or you are about to do/doing something that will make it worse, then push the "Start" button on the control panel in the appropriate workshop.

The air filter will run for 20 minutes, after which it will turn itself off (do not turn power to the air filter off!). At any point the time may be extended by pressing the "Start" button again.

If desired, the fan speed can be changed by pressing the "Speed" button on the panel.

As a general rule, an air filter should be used when using any of the following machines/tools:

- Bandsaw

- Belt sander (free standing or handheld)

- Chop saw

- Track saw

- Workbee CNC

- Router (in table or handheld)

Music Server

The music server is running Logitech Media Server (LMS) on a Raspberry Pi using PiCorePlayer. There are currently 2 players, one in the main room and one in the basement.

Essential Information

- Responsible Person(s): Iain Y

Controlling the music

There are several ways to control the players:

- Using the media control buttons.

- Using the touchscreen mounted on the green pillar in the main room.

- Using http://mediaserver:9000 on a web browser whilst connected to the space WiFi.

- Using a compatible mobile app e.g Squeezer https://play.google.com/store/apps/details?id=uk.org.ngo.squeezer

- Alternative Android Apps https://wiki.slimdevices.com/index.php/Remote_control_apps_for_Android.html

- Alternative iPhone Apps https://wiki.slimdevices.com/index.php/IPhone_control.html

Media Control Buttons

There are Media Control buttons for each player:

- In the main workshop, on the second bank of desks.

- In the basement, in the corner of the South side, next to the amplifier.

Green (Play/Gamble) button:

Short Press = Play/Pause - If there is nothing in the playlist it will start random play.

Long Press (2 Seconds) = Switch the Favourites (which should contain a list of radio stations).

If the light is flashing, it should indicate the music is paused, it should be fully on whilst playing.

Red ("Fire") button

Short Press = Skip Track

Long Press (2 Seconds) = Clear the current playlist.

The light comes on when you press the button and goes off when the Long Press is reached.

Amplifier control

In the main workshop, the amplifier is switched on and off by the Media Control Buttons based on the status of the player. The controller

In the basement, the amplifier must be switched off manually when not in use.

Adding music to the server

The music is stored on a share on the server at the following location: \\mediaserver\music\

Music can be in MP3, OGG, FLAC, WAV or WMA.

The folder structure should follow Artist > Album > Tracks.

Tracks should be properly ID3 tagged before being copied into this area. A tag editor can be used to edit your files e.g. http://www.softsea.com/review/ID3-Tag-Editor.html.

Modified Bosch Tassimo machine

A Bosch Caddy TAS70 Tassimo drinks machine that has been modified to produce ~90C water.

You can still use it for making Tassimo drinks, as long as you enjoy creating a waste product that contains four waste streams and is a pain to separate and not widely processed.

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): Dan Nixon

Getting water

- Turn the machine on via the switch on the right hand side

- Lift/open the Tassimo disc loading bay lid

- Close the Tassimo disc loading bay lid

- Push big button (it is a little sticky, ensure it does not get stuck in)

- ???

- Water appears (hope you put your mug under the spout)

Currently you cannot control the temperature or quantity of the water. Maybe you will be able to in the future (but probably not...).

Resources

- Manual

- Quick Start Guide

- Discs

DeLonghi Magnifica coffee machine

We now have a coffee machine that makes (generally) pretty good coffee.

It's a bean to cup machine, which means you put whole coffee beans in, and it will grind them and make coffee.

It's a DeLonghi Magnifica ESAM4200 S.EX1, and the manual can be found here.

Essential Information

- Location: Ground Floor Workshop

- Responsible Person(s): David Pye

Coffee Bean Supply

It's new to us, so we haven't got everything straightened out yet. At the moment, the Space has not yet decided to fund the purchase of beans ( and might not, depending on the cost, and the level of interest).

So there are a few options we can discuss:

- The coffee drinkers can buy beans in turn (or every now and again) so we all have access to coffee.

- Keep a bag of beans in your box, and throw a handful into the machine when you want coffee. (discourages freeloaders...!)

- We could discuss, once we know likely usage/cost, whether the space might fund the beans like it does tea. But if it's much more expensive, it's not necessarily fair.

- We could have a coffee kitty and set a price for a cup.

Using it/Troubleshooting

Warning: Beans go in the grinder hopper at the top. Water goes in the pull out water container. Putting water in the grinder hopper will cause much distress to the maintainers. We've spent an evening overhauling the seized grinder after someone poured water in it, and it rusted solid.

Procedure

- Water goes in the water tank to the right. Tuck the milk frother spout in so its' out of the way, and pull the water tank forwards, refil (note the MAX mark) and replace.

- Coffee beans go in the hopper on the top left under the black cover.

- The two silver dials - the one on the left sets the amount of water i.e. volume, the one on the left sets the amount of coffee - ie strength.

- It makes espresso, so you probably want to press the two-cup button at the top to make a mug of 'latte/cappuccino' etc.

- Press the top right button (with the picture of steam above it) to activate the steamer. When it's solid red, crank the steam knob half a turn anticlockwise to start steaming. A milk jug is provided. Please wash the jug and the removable spout after use.

Most common warning/status lights:

- Bottom left: Needs water - top it up.

- 2nd from left: Empty the grounds container. Gently hinge the centre section out, and pull the drip tray mechanism OUT. The grounds container is at the back. Ask someone to show you if you're not sure, it's difficult to describe in writing!

- Middle one: 'generic error'. Might be the centre section door not shut properly. Else, it's broken. Bugger. Tell David Pye/post on -admin mailing list.

- 2nd from right: blinking - needs descaling.

- Far right: ECO light. Should be on. Don't press the button to turn it off, it won't turn off automatically, and will waste power.

Wiki

This section describes a little about the wiki, how to use it and how to write content for it.

The wiki uses mdBook, the content is hosted on GitHub and the site is hosted on Cloudflare Pages.

Essential Information

- Responsible Person(s): Dan Nixon

Contributing content

If you would like to make some changes to the wiki, have a read of the style and contributing guides.

Wiki style guide

The key words "MUST", "MUST NOT", "REQUIRED", "SHALL", "SHALL NOT", "SHOULD", "SHOULD NOT", "RECOMMENDED", "MAY", and "OPTIONAL" in this document are to be interpreted as described in RFC 2119.

- File and directory names must be

snake_case - Text should be formatted as one sentence per line (i.e. a newline should always follow a

.) - Each document must make correct use of headings, i.e.

#as the document title, incrementing by one (##,###, ...) for each subsequent level of nesting desired - Unless referenced elsewhere, photos should be either in the same directory as the document that references them or in a directory named

imagesin the same directory as the document that references them - Photos should be cropped to only show what is relevant to the document

- Photos should be of an appropriate resolution (i.e. high enough to resolve sufficient detail, but low enough to not be excessive in size or page load time)

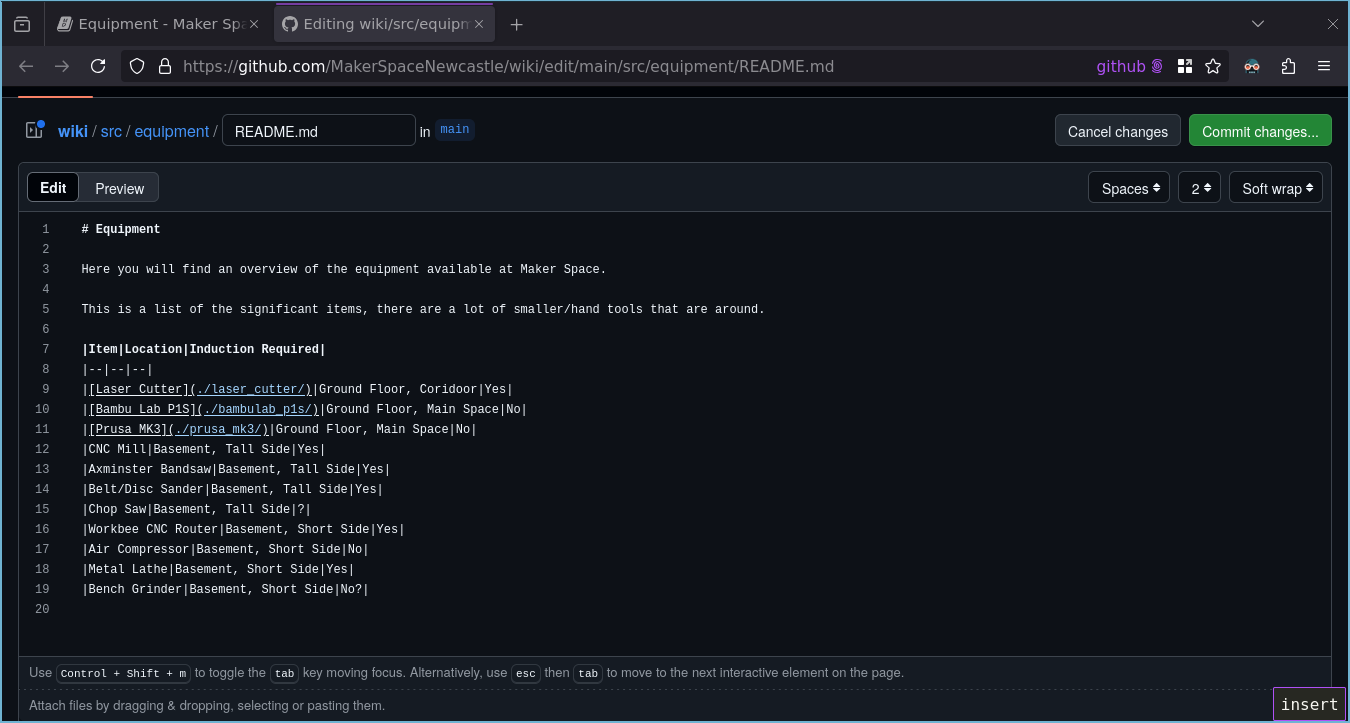

Contributing to the wiki

This outlines the means of editing the wiki.

If you are familiar with Git, then you can likely skip most of these docs, install mdBook locally and contribute as you would to any other project. The one caveat is that if you wish to use the CI generated previews then you must not work from a fork of the MakerSpaceNewcastle/wiki repository (you do not need to as being a member of the MakerSpaceNewcastle organisation gives you write permission to this repository).

Relevant parts of the mdBook documentation to reference are:

Prerequisites

- A GitHub account

- Be a member of the MakerSpaceNewcastle GitHub organisation

- Git installed and configured (if following Locally via Git clone)

- mdBook installed (if following Locally via Git clone)

Single page via the GitHub web UI

This will walk through making a change to a single page of the wiki.

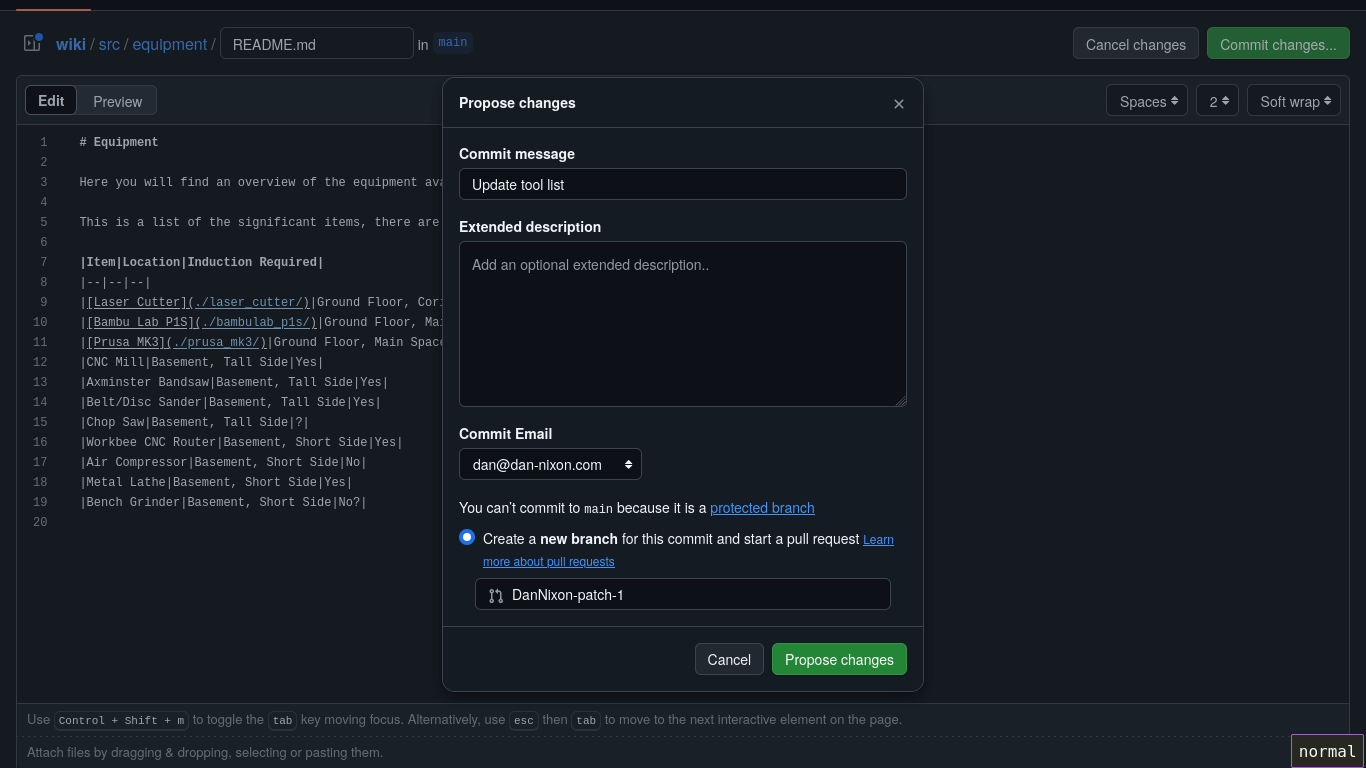

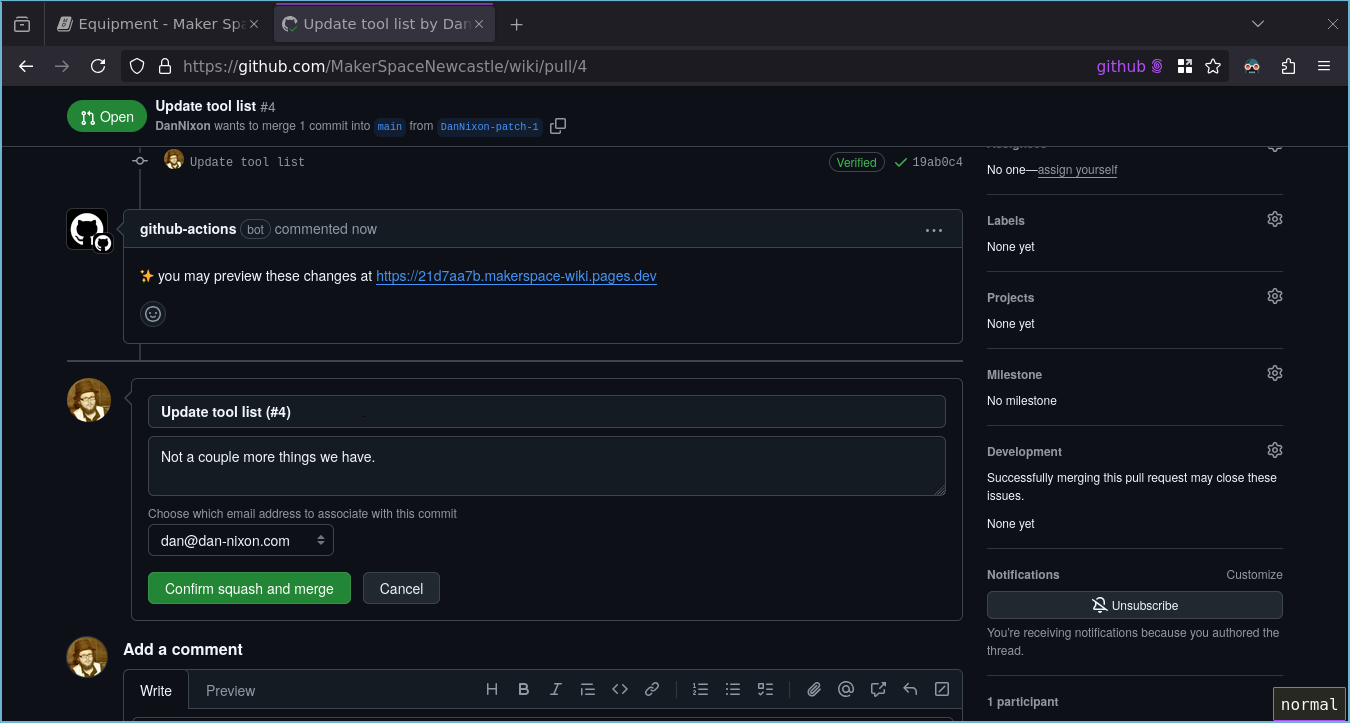

In this example, let's assume you wish to add a couple more tools to the equipment page, only adding them to this list, not creating their description pages.

-

On the page, click the edit icon in the top right hand corner:

-

This will take you to the online text editor on GitHub (if you are not already signed in then you will be asked to). Make the desired changes (in this case the addition of the air compressor and bench grinder to the list) and click the green "Commit changes..." button.

-

You will be asked to provide a commit message, type something descriptive here and click the green "Propose changes" button.

The remaining options may be left as their defaults. If the options provided to you look different to the above then verify you have satisfied the prerequisites.

-

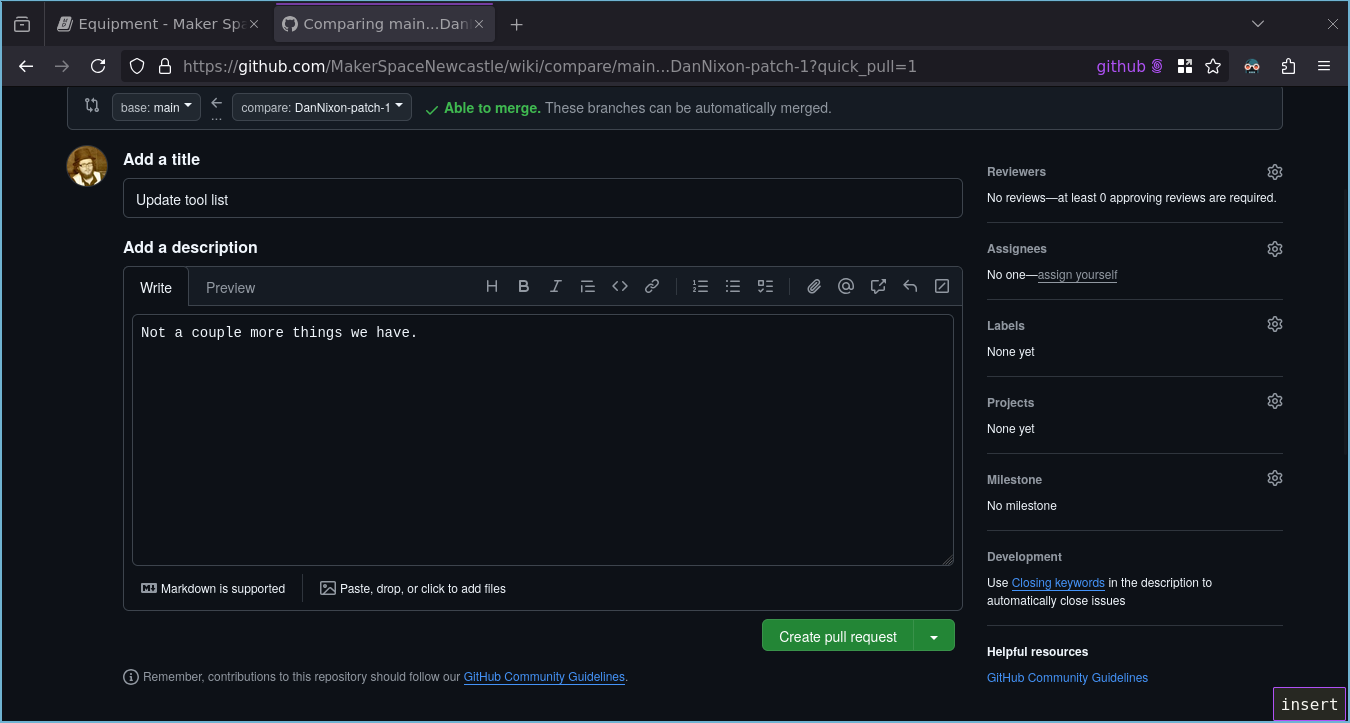

You will be taken to the create pull request screen, proceed to Proposing changes via a Pull Request.

Locally via Git clone

Note that these instructions are quite brief for the time being.

- Clone the wiki repository.

- Inside the repository, run

mdbook serve. This will start a local web server that will update the site live as you make changes. - Make your changes via your text editor/IDE of choice.

- Commit the changes to a new branch.

- Push the branch.

- Open a pull request, proceed to Proposing changes via a Pull Request.

Proposing changes via a Pull Request

-

Provide a suitably descriptive title and description of your changes and click the green "Create pull request" button.

-

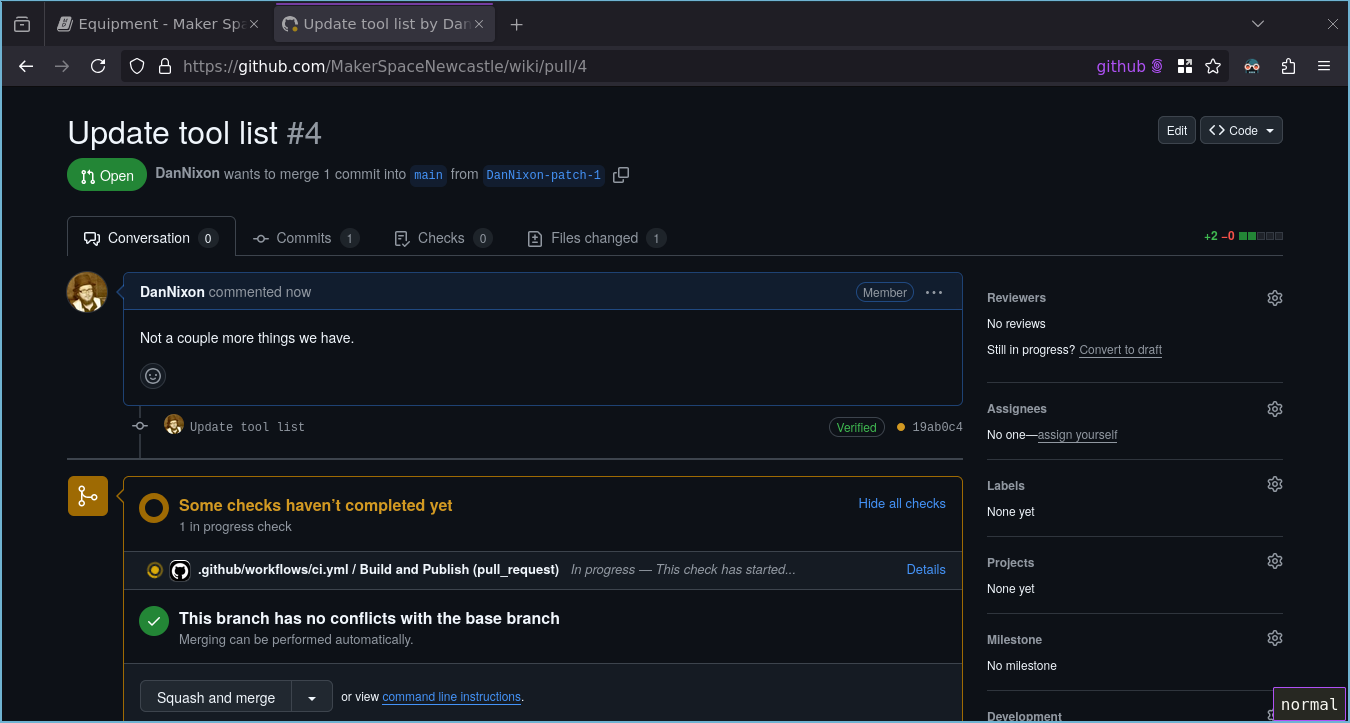

One the pull request has been opened, you will see the actions start to run. This will build the site and deploy a preview of it.

-

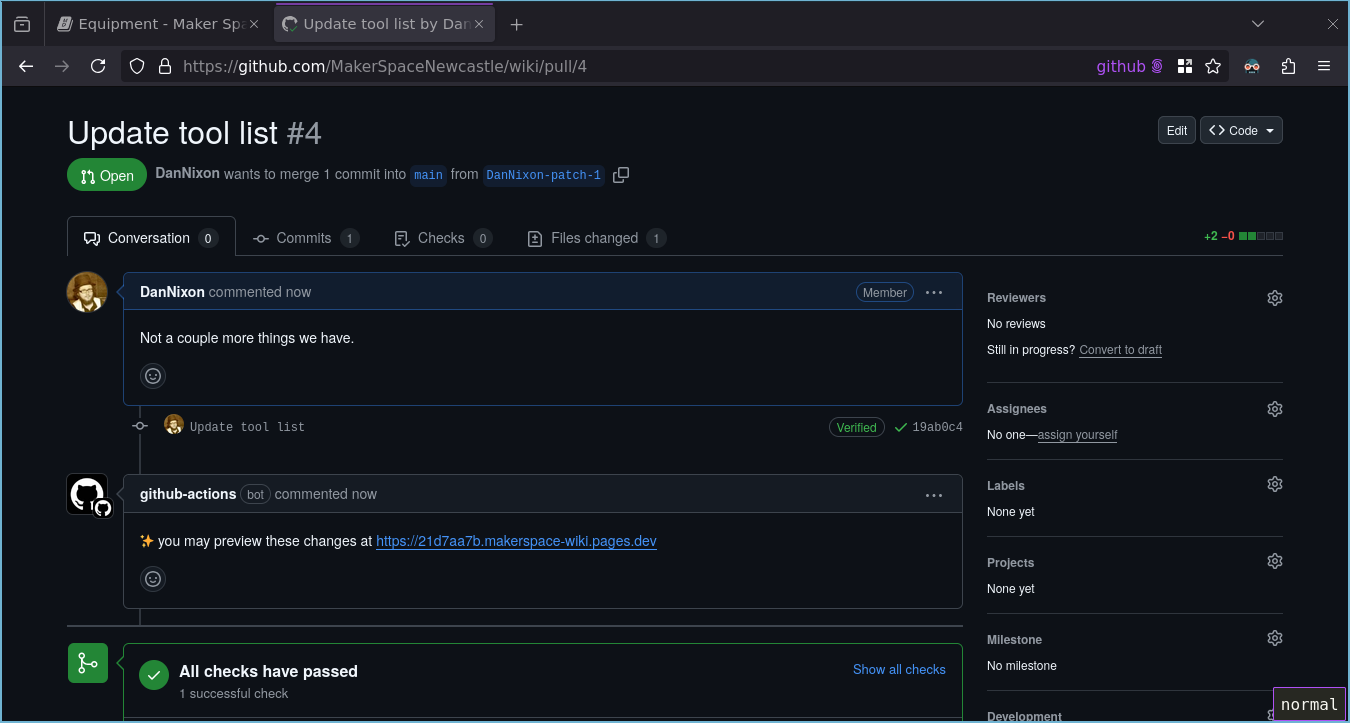

Once the actions have completed, you will see a comment appear with a link to preview the changes.

-

Opening the link in the comments and browsing to the equipment page shows the changes made.

-

Depending on exactly what has been changed in the pull request, certain people may have automatically been requested to review your changes, if so they must provide their reviews first. You may also opt to ask people to review your changes if desired.

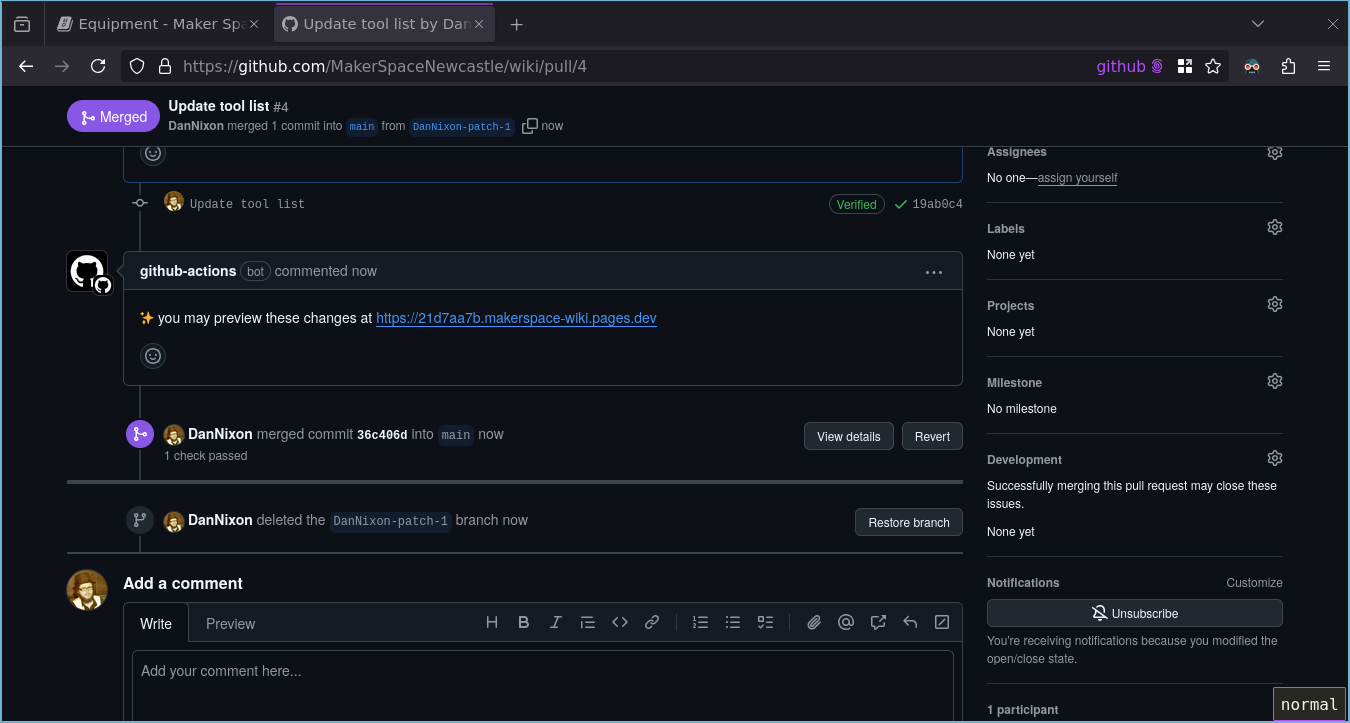

Otherwise you can now click the green "Squash and merge" button, followed by "Confirm squash and merge" to accept the proposed changes.

-

The pull request is closed, the live wiki will now update.

Policies and Procedures

This section describes how Maker Space is managed.

New Members

When joining Maker Space, new members start by filling in an application form which can be found here: https://www.makerspace.org.uk/joinus/

The New Member Procedure explains the process in more detail.

The last step of becoming a member of Maker Space is to go through a general induction. This covers the basic health and safety points, where to find things, what to expect of the space and what we expect of you.

Making changes in the space

Maker Space members are welcome to make and suggest changes in the space. We have a Change Proposal Procedure for proposing and making changes in the space.

Becoming a Keyholder

Most Maker Space members are keyholders, giving them 24hr access to the space. Our Keyholder Policy outlines what we expect of you as a keyholder.

To become a keyholder, you must be sponsored and seconded by existing keyholders and go through the Keyholder Proposal Procedure.

Behaviour Policies

Please, just be nice. We don't want to have to use our Code of Conduct or our Grievance Procedure.

Checklists

Some quick reference checklists to make sure tasks are done correctly and completely. These are not meant to be training or even documentation of a procedure, they are just to ensure that things are not missed.

Opening Maker Space

Note that the only "approved" way of opening the space is via the main door (i.e. the one with our sign above it).

Hallway:

- Main door: unlocked and opened

- Main door Yale lock: disabled

- Main door: closed

- Alarm: disarmed

Main workshop:

- Doors: unlocked and latched

Rear/courtyard foyer:

- In/out status: in

- Shutter: opened

Closing Maker Space

Basement:

- Equipment: off

- Access controllers: logged out

- Door: closed and locked

- Stair gate: closed

- Light: off

Rear/courtyard foyer:

- In/out status: out

- Shutter: closed if building unoccupied

Main workshop:

- Basement key: on hook

- 3D printers: off

- Fans/heaters: off

- Solder station: off

- Coffee machines: off

- Installations/displays: off

- Other equipment: off

- Windows: closed

- Lights: off

- Doors: closed and locked

Hallway:

- Laser cutter: logged out

- Lights: off

- Alarm: armed

- Main door Yale lock: latched open

- Main door: closed and locked

New Member Procedure

1. Application

The Applicant will start the process by completing the Membership Application Form which can be found here: https://www.makerspace.org.uk/joinus/

The Applicant should ideally have visited the space before submitting the form but this is not an absolute requirement.

2. Review

The Membership Officer and/or the Board will review the application and decide if it should be approved or not.

3. Approval/Disapproval

Approval/Disapproval should be confirmed by the Membership Officer/Board.

On Approval, the Applicant should be sent details of how to set up monthly payments and how to arrange their induction.

The Approver is not responsible for the actions of the Applicant.

4. Payment Verification

Membership Payments should be verified before the Applicant becomes a member.

5. Member Inductions

New members must receive an induction to cover the basic safety points, policies and expectations of the space. Inductions should be given on a voluntary basis and could be given by any member who has already been inducted.

The induction can be found here

- Inductions should ideally be arranged in advance.

- The keyholder for the session should not be obliged to give an induction.

- A member may wish to give an induction in order to meet the new member.

6. RFID Key Fobs

Once the applicant has become a member, an RFID Key Fob (if available) may be registered to the new member.

- Key fobs are available for a small donation but if the new member has a suitable key fob, this may be used.

- See the Access Control page for more details.

Safety Policies

All members are required to read and acknowledge Maker Space's Safety Policy and Lone Working Policy which can be found here:

These documents are to be reviewed and updated on at least an annual basis.

MS4 Induction checklist

This is a checklist of the things that a person who is inducting a new member to Maker Space should cover during their initial induction tour.

Introduction

Maker Space is a community owned and run working space. We've all clubbed together to get a space to work in. There aren't any grownups looking after this place, its just us, and it works because everyone pulls their weight to keep it running and nice for us all.

If in doubt, ask the mailing list.

- It can be found on the website header -> discussion list

- There is also a private list for members which is for the running of the space. You should have been added to this when you became a member - if not, please say something as you'll be missing out on key announcements.

Access to the space

- Access is available if a keyholder has opened the space. i.e. Welcome Wednesday and regular evening sessions.

- If you need access outside of the normal hours, ask on the discussion list as a keyholder may be planning to be in.

RFID Access

- RFID fobs can be used to access:

- The space, when a keyholder is in.

- Machines that require an induction.

- If you have a compatible fob already, you can use that. We also have some fobs available if you don't.

- Register your fob by swiping the main door a few times and letting an admin know when you did it.

General Safety

- Fire exits - keep clear! / Fire Extinguishers / First Aid Kit

- Be mindful of smoke alarms.

- What to do if fire alarm goes off - muster outside - if you find a fire, sound the alarm, yell etc, then leave.

- Fire assembly point is in the car park at the back of the building.

- Don't leave things on the floor where people might trip over them, bags, cables, project boxes etc, tripping over hurts

- Use ladders when required rather than chairs, tables etc. and make sure it's stable.

- Be mindful of others if you're doing something that might impact on them or if they might. e.g. working in doorways, walkways etc.

- Do not work on live mains electricity, it's quite dangerous.

Toilets / Water / Drainage

- Toilets near entrance.

- Drinking water from Kitchen.

- If you're covered in oil or grease, cleaning supplies (Swarfega etc.) are available. - Currently downstairs by the lathe.

Using the Space

People use the space differently, please be considerate.

- Avoid telling people how to do their project. Sometimes the objective is to learn a new technique rather than solve the problem in the best way.

- Try not to touch or pick up projects without permission.

- Some people are here to be social, some people are here to work and may not want to talk. Please respect their space and leave them be!

Infrastructure/security

- While many things are fair game for hacking/modifying, the core infrastructure/access control systems are not.

- Attempts to 'defeat' security/access control for equipment will be viewed very negatively and may end up in restriction/removal of space access privileges.

- If you want to improve a piece of core infrastructure e.g. music player etc, then discuss any proposed changes with its' current owner/maintainer first.

Parts/Materials

- We have lots of scraps, off-cuts, spares and components etc. which can be used.

- If you need something specific or a lot of something, please provide your own.

Maker Space has a clean desk policy

- Try to tidy up as you go if possible. Work spaces should be clean and tidy before you leave.

- If you need to leave something out, ask on the discussion list.

- Bins, dustpans, brushes, mops, blue roll and vacuum cleaners etc. are around the space.

- If you have cut, sawed, drilled, sanded, filed or ground anything then there will be something to clean up.

Bins

- Large bins in the workshops - Dustpans and brushes attached.

- Small bins around the space.

- Please do not leave food waste in the space.

- Bins currently to be taken home. Please help out if you can (but only if you will dispose of waste streams correctly).

- Battery disposal - Please take to a battery recycling point e.g. Tesco.

- Recycling - in workshop.

- Small electronics/e-waste in marked box in entrance lobby.

- Do not bring waste into the space just to dispose of it.

- (see Waste Streams)

Entrance Lobby

Main door

- This is our main door and a fire exit route.

- (demonstrate opening it and using RFID when fob is issued)

Hack or Die

- Items on the shelves are for hacking and remaining items are periodically disposed of.

- Please only add items you realistically think will be used by someone.

- Please don't bring things in just for Hack or Die. Do that virtually (by email) instead.

Laser Cutter

- Induction required - Ask on the members list.

- Scrap material available for use.

Toilets

- Exist.

Workshop

Main room

3D Printers

- Induction required for Bambu Lab printers

- Filament is paid for by the users. See 3D Printer Filament for details.

- (further details given in induction)

Members' Store

- Your box goes here - 32L - 18cm (h) x 60cm (w) x 40cm (d)

- Please stack things carefully, especially high up.

- Ask on mailing list about storing big things in space, before you bring it in.

General Storage

- There's a mix of hackable and non-hackable things here.

- Vinyl Cutter

- Batteries / Power Supplies

- If in doubt, ask.

First Aid Kit

- On the end of the shelves

Basement Key

- Next to the first aid kit

- Unlock the basement if you need to, leaving the key in the door

- Leave locking the basement to the keyholder

Wall o' boxes and other material around space

- OK to use stuff, but please add stuff too - It's all provided by members and rather than the space.

- Please also apply 'fair use' principles to Space items - If you use a lot of something, replace it.

- Put it back in the box and on the correct shelf when done (boxes are colour coded to shelves).

- Glue gun - please make sure you let it cool before putting it away.

- There are "Please hack"/"Do not hack" stickers and labels. Please respect them. If labelling something, write "Please/Do Not Hack", your name and the current date.

Tea and coffee facilities.

- Coffee machine - used for hot water instead of a kettle.

- Bin bags - on shelves.

- Tea/biscuits/sweets etc often on the table - help yourself - feel free to add more

Fridge